After Xinhua News Agency's micro-video launched, its views quickly exceeded one million, and the micro-video attracted public attention. It successively appeared on the front pages of Xinhuanet, GMW.cn, People's Daily Online, and major mainstream media apps, which fully reflected that CISDI has conscientiously implemented the national strategies, practiced the concept that lucid waters and lush mountains are invaluable assets, promoted green and low-carbon industrial transformation through independent innovation, and conducted the vivid practice and obtained important achievements in cultivating and developing new productive forces.

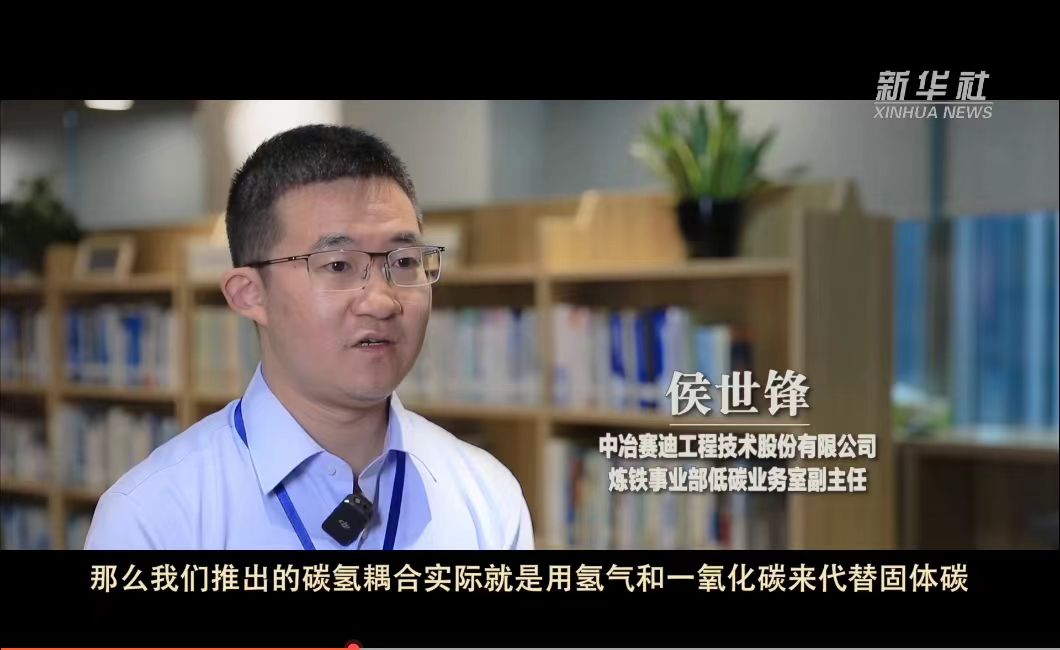

In recent years, all localities have adhered to the goal orientation of green development, explored green industrial structures and green production methods with higher scientific and technological content, lower resource consumption, and less environmental pollution, forming new growth points for economic and social development. CISDI has made unremitting efforts to explore new process routes for low-carbon smelting in blast furnaces and introduced the carbon-hydrogen coupling technology route, which is actually to mix hydrogen and carbon monoxide together and spray them into the blast furnace to participate in the reduction reaction, replacing part of the reduction reaction of solid carbon, to reduce the solid carbon consumption of the blast furnace. In May 2023, the 3R low-carbon blast furnace technology with high-efficiency reduction independently developed by CISDI was officially put into operation on two 2,000 m3 blast furnaces of Hebei Zongheng Iron and Steel Group. The new low-carbon smelting process of scale large blast furnaces that greatly reduces carbon emissions has thus entered the stage of industrial application. Since these two blast furnaces were put into operation, the average gas replacement ratio has been more than 0.5 kg/m3, which is about 5% to 10% less carbon emission than domestic blast furnaces of the same level, and the annual carbon dioxide emission reduction is about 400,000 tons.

In addition to low-carbon blast furnaces, CISDI is also exploring more carbon reduction routes. The direct reduction process with the self-developed hydrogen-based shaft furnace is in pilot-scale experiments. In the future, through industrial application, it will contribute more to the steel industry to achieve the "dual carbon" goal.